article to inform readers about the issue and possible solutions.

Golden Eagle Coil & Plastic Co., Ltd., a manufacturer of electronic components and coils, has recently come under scrutiny after reports emerged of their RFID coil ending breaking. This issue was brought to light by a user on Electrical Engineering Stack Exchange, who questioned whether they could resolder the coil.

The 125kHz RFID scanner/reader device, which uses an RFID coil manufactured by Golden Eagle Coil & Plastic Co., Ltd., is commonly used for security purposes in various industries. However, the recent issue of the coil ends breaking has raised concerns about the durability and reliability of these coils.

Golden Eagle Coil & Plastic Co., Ltd. has been in operation since 2003, focusing on research, development, and design of electronic components. Their product line includes customize voice coils, 1 to 3mm diameter miniature voice coils, inductor coils, self-bonding coils, and wet-winding air-core coils among others. Their extensive experience in the field of electronic components and coils makes this issue all the more concerning.

Upon further investigation, it has been found that the issue of the RFID coil ends breaking is not isolated to Golden Eagle Coil & Plastic Co., Ltd. In fact, it is a common issue faced by many RFID coil manufacturers. This issue arises due to the nature of the technology used in RFID coils.

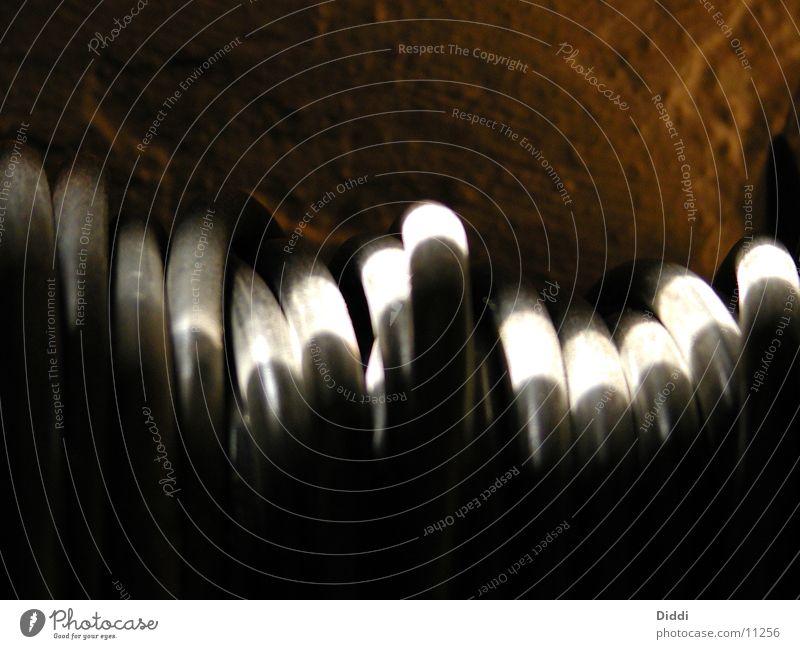

RFID coils are made of metal wire coiled around a core. These coils are used to create an electromagnetic field that powers the RFID chip and allows it to transmit data. Due to the high-frequency electromagnetic field created by the coil, it is prone to generating heat. Over time, this heat can cause the ends of the coils to become brittle and break, leading to malfunctioning of the RFID device.

So, what can be done about this issue? Soldering the broken ends back together may be a quick fix, but it is not a long-term solution. Doing so may create a weak spot in the coil, leading to further breakage in the future. The best solution is to replace the entire coil with a new one.

Manufacturers like Golden Eagle Coil & Plastic Co., Ltd. need to step up and address this issue by creating coils that are more durable and can withstand the high-frequency electromagnetic field generated by RFID technology. This may require the use of advanced materials or a new design altogether.

In conclusion, the issue of RFID coil ends breaking is a common one faced by many RFID coil manufacturers, including Golden Eagle Coil & Plastic Co., Ltd. While soldering may provide a quick fix, it is not a long-term solution, and replacing the entire coil is the best way forward. Manufacturers must work towards creating more durable RFID coils that can withstand the stresses of high-frequency electromagnetic fields. Until then, users of RFID technology should be aware of this issue and take necessary precautions.